Plenty of resources are out there for anyone who wishes to implement a new 5S program at their workplace. Learn what each “S” in 5S stands for, why it is effective, and why management often chooses to utilize this exceptional organizational tool.

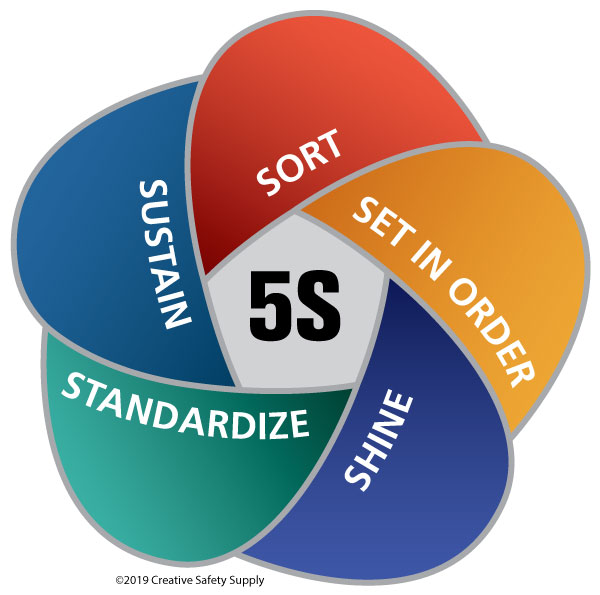

Seiri, Seiton, Seiso, Seiketsu, and Shitsuke are the five Japanese terms for 5S. Sort, Set in Order, Shine, Standardize, and Sustain are the English terms. These are the five essentials to workplace organization and for a safety culture shift. It is sometimes best to take a look at some specific examples of 5S strategies to see how the method could be used in a more practical situation.

Sorting Methods for 5S

Sort is the first S. The point of this step is to ensure everything in the workspace is kept in its proper place so it is easy to locate, won’t get lost, and can be taken care of. It must also be noted that objects not in use, broken, or otherwise out of commission must be removed. Overall, tools and objects that are easy to find helps to boost productivity in the workplace.

A simple example of this organizational effort would be in an auto-mechanic shop where every single tool used in the facility is assigned a specific location to be kept when not in use. Compared to having to search through a general ‘tool area’ every time something is needed, this will save countless hours each year and offer many other advantages as well.

Set Items in Order for 5S

After an area has been properly sorted through to toss the unnecessary items and keep essential tools, it is then time to set everything in order. The Set in Order step goes hand in hand with Sort but takes organization to the next level. Rather than just assigning an item to one spot, the 5S team will analyze where that item will be best kept.

In the example of the mechanic’s shop, an item like an air-hose that is used constantly will be kept very close to the work area. Another tool that is only needed on rare occasions should be stored in an out of the way location. A facility that is properly set in order will operate far more efficiently.

Shine: 5S Housekeeping Essentials

Most people believe the ‘Shine’ step in 5S is just keeping things clean, but that is just the beginning. In addition to keeping a facility clean, shine means to keep everything in proper working order. That means taking the time to perform safety inspections, regular maintenance, and daily housekeeping duties. The idea here is to proactively clean and maintain to prevent future breakdowns and the general accumulation of dirt and grime.

An excellent example of Shine in the 5S process again resides within a mechanic’s garage. Performing duties with Shine in mind could include making sure all equipment is properly lubricated. This is on top of wiping down workstations, ensuring tools are kept clean, and sweeping up any messes right away.

Standardize the Workplace

Once everything is in its proper place and kept in proper order, it is time to ensure everyone is doing things the proper way. Standardizing is an easy concept to understand, but a difficult one to implement. When a facility finds the best way of doing something, everyone should do it in the same way every time. This helps prevent any miscommunication and helps achieve a predictable final product that has value to both the customer and the employee.

An automotive example of this can be seen at any racing track. Everyone has seen how all the pit crews change tires in the same way, and it is clearly the fastest possible option. While this may be extreme, it is a proven strategy that has been replicated across the industry.

Sustain 5S

Once changes have been made in the workplace, it is necessary to try to ensure the improvements are maintained long into the future. The best strategy for this is to continuously monitor progress and provide immediate feedback should something change. In addition, offering new employees proper training to ensure they do things in the way that has been proven effective.

These are, of course, just simple examples of 5S strategies. Every workplace will need to identify where they can make their own improvements and use the 5S system to get the best results. The next level up in the world of Lean manufacturing would be to implement Six Sigma principles to reduce defects in the work process.

Similar Questions

- How can 5S be used in different industries?

- How does 5S improve safety?

- How does 5S increase workspace productivity?

- What are the 5 S’s and what do they stand for?

- What is 5S housekeeping?

- What is the 5S methodology?

- How do you implement 5S in Office Environments?

- What are the principles of 5S?

- Who should implement 5S?