The activities used for process mapping are part of the overall quality management practices of a business. When done correctly, a process map will look at a single objective within a procedure and help measure it against the company's overall goals to ensure that all work being done helps achieve process improvement. In short, anything that is not contributing to the main goals of a business is considered waste and will therefore be eliminated.

What is Process Mapping?

Process mapping is a term used to describe any activities involved in identifying what a business or department does, who is responsible for doing it, the standards to which it should be done, and how successes will be measured. This type of process improvement is used in many types of businesses to help companies streamline their production, increase profitability, build an understanding of the procedure, reduce waste, etc.

The best way to create a process map is to use what looks like flow charts. Flow charts specifically made for process mapping allow the users to see the entire process from beginning to end in detail. The visual communication of ideas is what helps speed up the improvement process since every step is broken down into bite-sized pieces. By going through each step one by one, the creator and those around them have the chance to analyze how the current process can be improved which helps with planning new projects down the road.

Types of Process Maps

There isn’t just one type of process map. Numerous different process map formats exist, each one providing a different set of strengths and purpose to the work being done. The following are just a few examples that are relatively common in workplace improvement projects:

- Activity Process Maps represent all the value-added and non-value-added activities in a particular process.

- Document Maps are unique in that documents are noted as the inputs and outputs of a particular process.

- High-Level Process Maps are primarily concerned with the interactions between the company’s SIPOC connections.

- Rendered Process Maps work with both current and future processes to reveal areas needing improvement.

- Value Stream Maps are concerned with the improvement of processes that involve creating product or providing services to customers.

- Workflow Diagrams are basically flow charts. However, the UML symbols usually used in other process maps are not used.

Notice how each of these types of process mapping strategies aren’t just for manufacturing facilities. They can be for administrative work, office jobs, and any other occupation that relies on standardized procedures for efficient and productive operation.

The 4 Different Levels of Process Mapping

Each type of process map falls into one of four broader categories referred to as process modeling levels. Whether it be for value stream mapping, based on inputs and outputs, process documentation, or process flow. Those four levels are as follows:

- Level one is reserved for high-level maps. These outline processes are at the operational level such as administrative duties or customer processes.

- Level two process maps are often referred to as top-down process maps as they prioritize the flow of the procedure from the very beginning to the very end. These maps often flow across several departments within the facility.

- Level three process maps focus on the intricacies of completing a specific process within one operational area. This includes the roles that employees have, the inputs and outputs, etc.

- Level four process mapping utilizes process documentation, instructions, and procedures to complete level three process mapping. However, the added responsibility of this level is decision-making. The addition of decision-based process mapping makes this level one of the most useful, but one of the most energy-intensive out of all four levels.

Remember to make sure you are picking the correct level of process mapping as that has a large part to do with how successful the map ends up being for process improvement.

Simple Workflow Process Mapping

Workflow process mapping is often seen as an extremely complex strategy that will take a lot of time and effort to implement. While it can be as complex as needed, many companies find it helpful to break a full process map into smaller, more manageable parts. Creating simple maps for each process in the company can be done one at a time to break it down into bite-sized pieces.

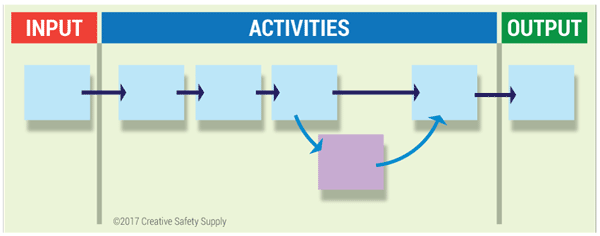

The following image shows just how easy it can be to create a process map for a single process. Enter the input on the left, fill out each of the steps necessary in the middle, and then the output on the right creates a full process map for each activity in a facility.

Why Business Process Mapping

When people think about process mapping, they often just look at it as a good way to document procedures, so everyone knows how things are done. While this is certainly one of the benefits of a process mapping strategy, it’s not the only one. The following are some of the many reasons why business process mapping is so popular and why all businesses should put forth the effort to implement it in their facilities.

- Training – Process maps are a key component in training new employees. Process maps can be given to them so they can see how things should be done.

- Problem Solving - When there are problems in the process, it will be much easier to see exactly where they are taking place. This can help find solutions to the problems much more quickly.

- Standardization - Standardization is a great way to eliminate waste and ensure consistency throughout all shifts, all facilities, and anywhere else where there would otherwise be variation.

- Big Picture - When a good process map is in place, everyone can see the big picture. This helps each department, or even each employee, see where they fit into the overall process flow.

- Compliance - In industries with regulations, a process map can be used to ensure everyone is in compliance with those regulations at all times. The map itself can even be given to inspectors to show how things are done to prove compliance.

- Team Involvement - When creating a process map for a company, all employees need to contribute by working on the steps they are involved in. This team involvement can help keep people engaged and even identify improvement opportunities that may exist.

Process Maps in Six Sigma

The primary goal of Six Sigma is to reduce the rate of variation in a process to achieve optimal quality control. Now, the addition of process mapping makes the optimization goal a little bit easier to see and therefore complete. The teams benefits greatly from coming to a consensus on how a process really works and how that process should be completed.

Because process mapping is so useful in this kind of environment, it is considered to be useful in any type of workplace that can integrate Six Sigma into the workplace culture. With that being said, all of the previously mentioned types of process maps can be used in environments where Six Sigma is being used! Overall, Six Sigma and process mapping go well together, since they help each other along in terms of process improvement.

How to Create a Process Map (Step-by-Step)

Creating a process map can be a time-consuming task. However, as long as the following steps are followed, there will be less confusion on what to do next as the flow chart creation progresses:

- Identify the problem – The most important question that needs to be asked in this step is “what process needs to be visualized?” Make sure to narrow this answer down to one process, otherwise it will be too much to handle all at once.

- Determine all the involved activities – This step includes who completes steps of the process. It will also be good to set the bar of what needs to be included in the description of each step.

- Determine the boundaries – Ask questions such as when does the process start or when does the process stop?

- Identify the sequence of the process steps – Now is the time to organize. Go through each step one-by-one. For now, just get the steps down, don’t worry about the special symbols.

- Draw the basic process mapping symbols – Once everything has been written out, then the group can decide on what defining symbols can be used for each step.

- Finalize the flowchart – Make sure to have others look over the process map to ensure nothing was missed or if anything is redundant. Those reviewers can be team members, workers, supervisors, suppliers, etc.

Process Mapping Tools and Techniques

When implementing process mapping, it can be beneficial to use specific tools. Depending on how the process mapping is being done, its complexity, and other factors, a facility can choose from many options. Companies can use pre-printed charts, which can be filled in with all the steps. This can be used either to make a complete process map or to create a rough draft before it is entered into something more advanced.

Another type of mapping tool is software that digitally creates the maps. Digital process maps have a lot of advantages since they can be easily edited and improved over time. They can also be copied and sent to other departments for further applications.

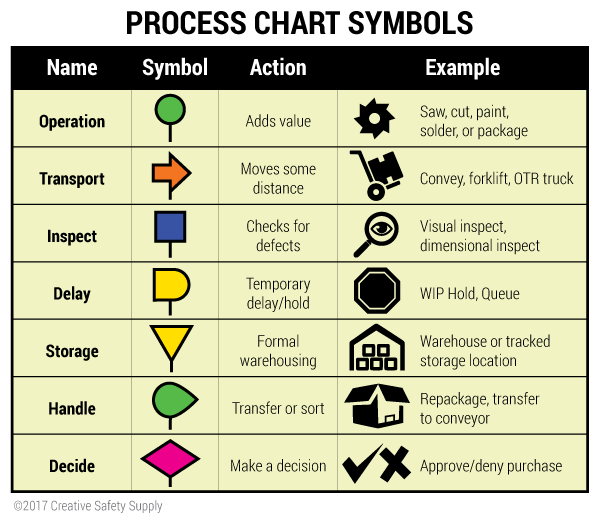

While there are many mapping techniques that can be used, the vast majority of them are laid out in steps. The map itself is 'written' just like normal reading, left to right, top to bottom. Shapes and symbols are used throughout process maps to identify the different components of the map. Some examples of the components to process mapping include:

- Decision Points - If human decisions need to be made during a process, a decision point is added to the process map.

- Documentation - When documentation is required, the process map has a 'documentation' symbol that identifies where the documentation is located.

- Transport - When the product parts need to move some distance, the transport symbol needs to be used.

- Handle - Anytime the products need to be handled by a worker, this is the symbol that should be used.

There are many other symbols used in process mapping. While there are no required standards that must be used across industries, there are some commonly used charts that have proven effective. The following image shows some of the most common symbols and what they are used for.

Other examples of Application

One of the best ways to understand this concept is to look at different process mapping examples. This can illustrate how different types of businesses benefit from the strategy. These examples will also show how the Lean strategy can be used in a variety of industries to effectively improve the way things are done.

Process Mapping for Manufacturing

The manufacturing industry is one of the most common places where process mapping is used. In the auto manufacturing industry, there could be dozens or even hundreds of different processes that need to be mapped. By looking at just one of the possible maps, it is easy to see how they can be beneficial. For example, one process creates the frame of the vehicles. Each vehicle model needs a different frame, and therefore a different process.

One step in each process is ordering or acquiring the materials used for the frame. The next is melting the metals so they can be formed into the right shapes. Cooling the steel, testing it for strength, cutting out any needed areas, and positioning the frame so other parts can be added are all additional steps. Simply put, every little thing that needs to be done in the manufacturing process is one step within the process map.

Process Mapping for Restaurants

The restaurant industry would follow the same general concept where each activity within the restaurant has its own list of steps that need to be taken. This starts with ordering the necessary ingredients and goes through the actual recipes that need to be followed to make each dish, the plating of the dish, and finally how it is to be sent out to the table for the customers.

Each restaurant needs to have its own list of process maps to standardize the way things are done. This will help ensure everyone, no matter which shift they are on, does things the same way so they are done efficiently, and so customers will always get the product they expect.

Process Mapping for the Office

In the banking industry, a process can be made for finding a new client and opening an account. This can start out with advertising to bring new potential customers into a branch. Once they enter, the bank employees go through the paperwork needed to open the account. Then any follow-up communications or other work needed to complete the process is done.

This is also a good example to show how one process map step can lead into another. Once a new savings account is opened, the process map can recommend additional services for the customers. Asking if they would be interested in transferring their retirement accounts, mortgage, or other financial services can be a great way to 'up-sell' customers. Using the process map can recommend the right products based on available information about the customers.

Similar Articles

- Value Stream Mapping (VSM Analysis)

- Understanding the SIPOC Diagram in Six Sigma

- Process Cycle Efficiency (PCE)

- 5 Lean Principles for Process Improvement

- Organizational Development Process

- Statistical Process Control (SPC) in Manufacturing

- What is Lean Logistics?

- What is a Kaizen Event? [Planning and Execution]

- What is QCDSM?