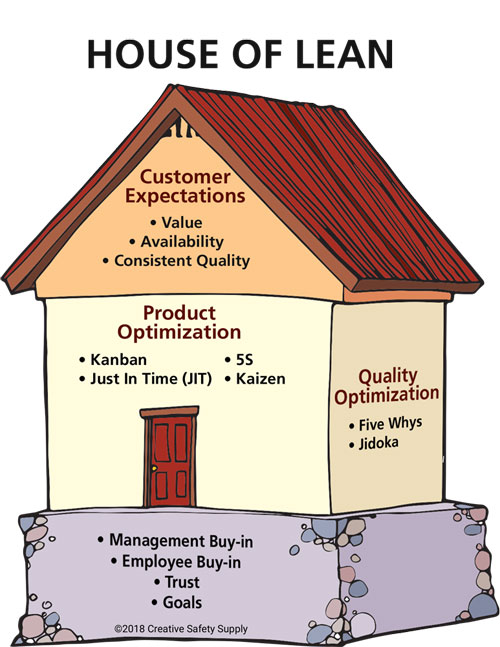

When learning about and implementing lean methodologies into a company, many people will refer to the process as the 'house of lean.' This is because just like a house must be built properly in order to stand, lean strategies also must be done in the proper way in order to be successful.

The different steps and concepts in lean can be associated with different parts of a home being built. When building a home, one must start with the foundation, then build the walls, and finally build the roof. When building a 'house of lean' the same thing must be done.

The Foundation

When starting any type of lean implementation, a company must build a firm foundation that will support the rest of the process. The following are the best places to start any foundation:

- Leadership - Lean methodologies don't have a chance at succeeding if the leadership team isn't on board. This starts at the very top of the organization and must work its way all the way down to the front-line supervisors.

- Employees - Employees must also be on board. Lean helps to bring employees into the fold by accepting their input and listening to their suggestions. It is also helpful to use lean to show employees how increased safety and efficiency can help them with their day to day jobs.

- Trust - Trust is necessary in order to avoid problems in any process. The trust must exist between employees and management, between each department, and even between individual employees. Making an effort to ensure everyone knows they are all working toward the same goals can help to build the trust that is needed for a solid foundation.

- Goals - Having clear goals in place for any lean project is essential. Without knowing what the desired outcomes are, it is impossible to ensure everyone is working toward them.

Along with those things, a company must ensure the foundation is steady and strong. The stability of a lean project is ensured by creating standards that are followed at all times. Successful companies will standardize all processes possible so that the outcomes are more predictable. Standardization also helps to find the fastest, safest, and best ways of doing things.

On its own, a foundation that includes well-thought out standards is going to ensure a specific project goes well. Building an entire company around the foundation of standardization will help to minimize waste and maximize profits.

The Walls

The walls of lean manufacturing, and lean in general, are going to optimize the processes that are in place. Improving efficiency, eliminating waste, and improving quality helps to ensure a company is producing the best quality products, at the lowest prices, possible. This is how lean can help to improve profitability, which will allow the company to grow and succeed for years to come.

Depending on the specific company, there are many ways that things can be optimized within any facility. In this sense, the 'walls' of the house of lean are going to be made from different lean tools and strategies.

The following are some of the most popular options to choose from, but there are others available as well. A company implementing lean will want to evaluate all their options and use the strategies that will work best for their particular situation. When looking at the house of lean, the walls are often split up into production optimization and quality optimization

Production Optimization

- Kanban - Properly managing the movements of different materials, products, information, and more is essential for any production system. The Kanban concepts use signals to indicate when a particular step in the production process should take place so that everyone is aware, and can operate more efficiently.

- Just in Time (JIT) Production - Just in time manufacturing has the parts and equipment become available as close to the time that it is needed as possible. This will help to reduce downtime, and reduce costs associated with warehousing items before they are needed.

- 5S - 5S is a type of visual management that helps to find and eliminate waste in the production process. The 5 S's are (in English) Sort, Set in Order, Shine, Standardize, and Sustain.

- Kaizen - This is a philosophy of continuous improvement. Kaizen concepts can be applied to both the production and quality optimization in many ways.

Quality Optimization

- Five Whys - As the name implies, five whys is a process where people will keep asking 'why' with the goal of identifying the root cause is found. Improving quality can be done by asking 'why' something is the way it is, and continuously digging into issues until the core of the problem is found.

- Jidoka - Jidoka is a way for an automated system to identify problems in the quality of individual products. When a problem, or defect, is found the production is halted until the cause of that issue is found and addressed.

The Roof

In the house of lean, the roof is customer focus. Keeping the customer's specific wants and needs in mind at all times is what will protect the rest of the structure from running into problems. Product optimization in the previous step is essential, but if a product is optimized only for the sake of improvement even though the customers don't want or need the new feature, it is a form of waste.

When implementing the roof of the house of lean, a team must consider all of the following things:

- What do Customers Value - Every feature and option on a product should be there specifically because customers are willing to pay for it. If they aren't, then it is simply a form of waste and should be eliminated in order to reduce costs.

- Value Stream Mapping - Value stream mapping is a useful strategy in determining where the value is needed in any product.

- Creating Flow - Having products flow through the established systems will ensure the systems are efficient, and always focused on the desired outcomes for the customers. A properly flowing production line will continuously deliver exactly what the customers want.

- Reducing Variation - Customers want a specific product, and they want it to be of predictable quality every time they make an order. Finding ways to identify variation in production, and eliminating it, will help to reduce variation and improve customer satisfaction.

These concepts help to form a barrier of protection that can offer guidance to the other steps in the house of lien. By focusing only on what the customers actually need, processes are able to be crafted that are focused on attaining the right goals. Without the roof, the rest of the house will eventually fall and crumble down because of having the wrong focus.

Resources

- https://www.isixsigma.com/cause-effect/determine-root-cause-5-whys/

- https://en.wikipedia.org/wiki/Value_stream_mapping

Similar Articles

- 5 Lean Principles for Process Improvement

- What is Toyota Lean Management?

- Kaizen and Lean Manufacturing

- Toyota Production System (TPS & Lean Manufacturing)

- Lean Thinking: The Foundation Of Lean Practice

- What is Lean Logistics?

- Kaizen (Lean Continuous Improvement)

- Understanding the Principles of Lean Construction

- Lean Supplies