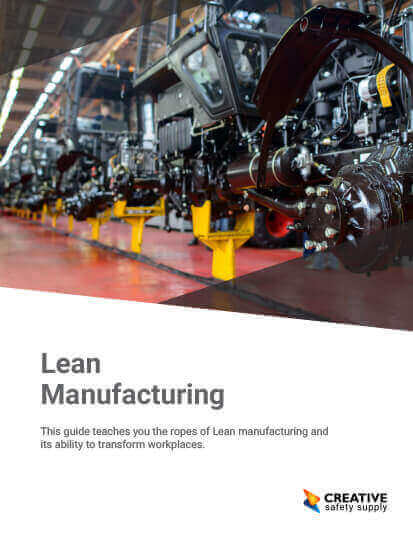

5S & Lean Manufacturing

Visual communication for productive facilities.

If you want to improve efficiency in your workplace, Lean manufacturing principles like 5S can help. Lean labels are built to help effectively communicate vital information about organizational and safety matters quickly and clearly.

Asset Tagging

Increase security with better asset management.

Asset tagging systems enable you to find the tools you need quickly. There’s nothing as frustrating as misplacing equipment; asset tagging drastically reduces this, and also decreases the chance of lost or stolen assets.

Barcode Labeling

Improve your inventory management with a barcoding system.

Barcodes allow warehouse managers to easily track inventory and better navigate spaces. Barcoding makes it easy to locate exactly what you need without needless wandering and guessing. Work smarter. Barcodes can help.

Equipment Labeling

Stay organized and efficient with equipment labeling.

Equipment organization means your workers are spending less time looking for the tools they need and more time doing their jobs. These labels are designed to be intuitive and hard-to-miss, which means organization stays consistent.

Rack Labeling

Manage warehouses and inventory more efficiently.

For warehouses, finding what you need quickly is the key to efficiency. Rack labeling allows workers to navigate these vast areas with speed and accuracy. Avoid waste and work smarter. Let rack labels help.

Stencil Tagging

Improve visual communication in your facility.

Labeling is smarter than stenciling. For years, stenciling has been a common way to label larger piece of equipment like forklifts or bulldozers, but there’s a more efficient way: labeling with the LabelTac® family of printers.