-

Every facility has unique needs when it comes to labeling. Whether it be for OSHA compliance, safety, health, informational, or organizational reasons. We know pre-made labels don’t cut it for some special projects. That’s where our team here... More details

-

Label a receptacle as trash only so that recyclable items are not thrown away. Helps reinforce environmental awareness. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant... More details

Trash Only Label

$3.75 -

Reminds personnel to recycle whenever possible. Helps increase environmental awareness. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant Removable without leaving messy... More details

Recycle Label

$3.75 -

Mark hazardous waste bins and disposal locations to prevent accidental contact and reduce health risks. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant Removable without... More details

-

An effective reminder for your workers to follow the 5S principles, which helps in the "sustain" portion of the program. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant... More details

Remember 5S Label

$3.75 -

Label a receptacle as a general recycling container that can take all types of recycleables. Helps prevent trash contamination. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear... More details

-

Mark areas specifically for storage. Helps prevent misplacement or storage in the incorrect area. Great for 5S labeling to sustain organization for efficient work.MINIMUM QUANTITY OF 2 LABELS PER ORDER More details

Storage Area Label

$3.75 -

Label a receptacle for metal scrap. Helps ensure proper recycling of metal. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant Removable without leaving messy residue Same... More details

Metal Scrap Only Label

$3.75 -

Label hazardous waste storage locations so proper care is used during operation or transportation. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant Removable without... More details

-

Notify personnel and others that only glass recycling is to be contained inside the receptacle. Helps prevent cross contamination of trash and different recycleables. 3 size options available Easy peel-and-stick application Strong adhesive for high... More details

Glass Only Label

$3.75

Six Sigma Labels

Implement Six Sigma into your entire

facility and achieve black belt status.

Six Sigma helps reduce the number of product defects to levels that are near-zero. The five steps of this ideology make achieving this efficiency fairly straightforward. With Six Sigma labels, you can remind workers of these steps, as well as the corresponding belt levels. Defining, measuring, analyzing, improving, and controlling are easier than ever with a wide variety of communication options that help you prepare your facility for this popular improvement methodology.

Free Six Sigma E-Book

Reduce waste and improve quality control in your facility.

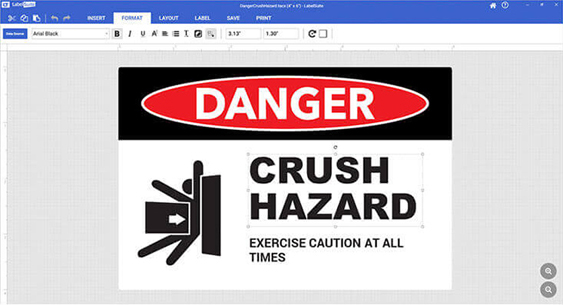

Encourage Six Sigma practices with LabelSuite™

While it may be difficult to get a black belt in Six Sigma, LabelSuite™ makes it easy to incorporate the methodology into your workplace. This software is user-friendly and brimming with Six Sigma templates.

Learn more about LabelSuite™Six Sigma made simple with LabelTac® printers

Incorporating Six Sigma in your facility is easy when you have a LabelTac® printer. This printer creates hundreds of labels that are resistant to smears and the elements. With an easy peel-and-stick application, you can put your Six Sigma labels anywhere and aid your workers in achieving black belt status.

Shop all LabelTac® Printer BundlesFree Six Sigma Resources & Related Articles

Lean 5S E-Book Free Guide

Learn how a simple organizational strategy can transform your business. Get the guidance you need to begin your 5S program with the help of this guide.

Lean Manufacturing E-Book Free Guide

Manufacturing experts have long discovered that devoting time and energy into evaluating processes with an eye toward improving efficiency and cutting down on unnecessary waste. Learn the ropes of Lean manufacturing.

Preventative Maintenance Free Guide

Preventative maintenance is all about being proactive. With a proper Preventative maintenance plan, you could extend the life of the machine, improve quality and consistent performance from the machine, and prevent costly—both financially and in time wasted—repairs when machine actually breaks down.

Six Sigma Articles > Lean Articles

Learn the essential elements of Six Sigma and the levels of certification. [Read Article]

Quality Control Articles > Lean Articles

Quality Control helps ensure products are meeting customer needs and reduce the risk of product defects. Let this article help get you started ... [Read Article]

Six Sigma Labeling Products

Helpful Resources